Introduction

In our next Potentially Genius® episode, the Tomorrow Lab® team meets with Jonathan Beri and the team at Golioth. As Jonathan explains, “Golioth is an ioT platform that helps product creators and engineers build connected products with their choice of flexibility of hardware in making it really easy to talk to the cloud. Our founding function is allowing users to work with the chips and connectivity options that best suit their needs as a product or electrical engineer and then simplifying the cloud part so the user does not need to set up databases and servers that may prevent someone from building the device.”

Jonathan challenged Tomorrow Lab to use the Golioth platform in several ways: find a use case for the platform that explores device settings management, remote procedure calls, and data logging capabilities.

What are GlowGuards?

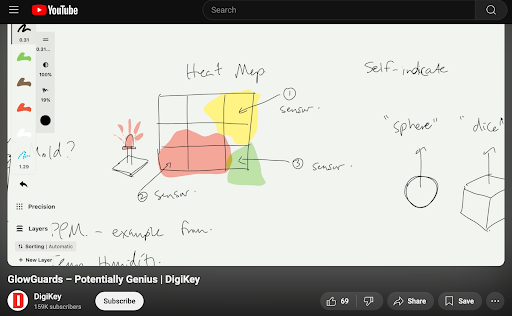

The Tomorrow Lab team got to brainstorming right away. A few ideas were tossed around: an environmental sensor for indoor building air quality, usage and activity sensors for machine use time like a laptop or bandsaw, and presence detection sensors for securing indoor spaces. Ultimately, the team landed on moving forward with a device and sensor network that identifies and displays poor air quality sources in rooms or buildings. Ted Ullrich, one of Tomorrow Lab’s partners explains that for this device “using Golioth as the central hub, sensors can join or leave the network reporting data for processing, then Golioth directs sensors to show colors creating a dynamic air quality heat map device in the room.”

Dorian, one of Tomorrow Lab’s electrical engineers, walks us through his component shopping cart on Digikey:

Shuang, another TL electrical engineer, works on the enclosure design for the electronic components. The opaque enclosure will hold the LED, which will funnel light through a diffusion rod. It will also hold the microcontroller, all the sensors and the PCB to help hold everything in place while the rod is in movement.

Ted and Shuang work together to test the sensors, which respond to moisture and temperature. When moisture is sensed after Ted lightly sprays towards the sensor, the LED changes green to red, and then when dried fades back to green. The test is a success!

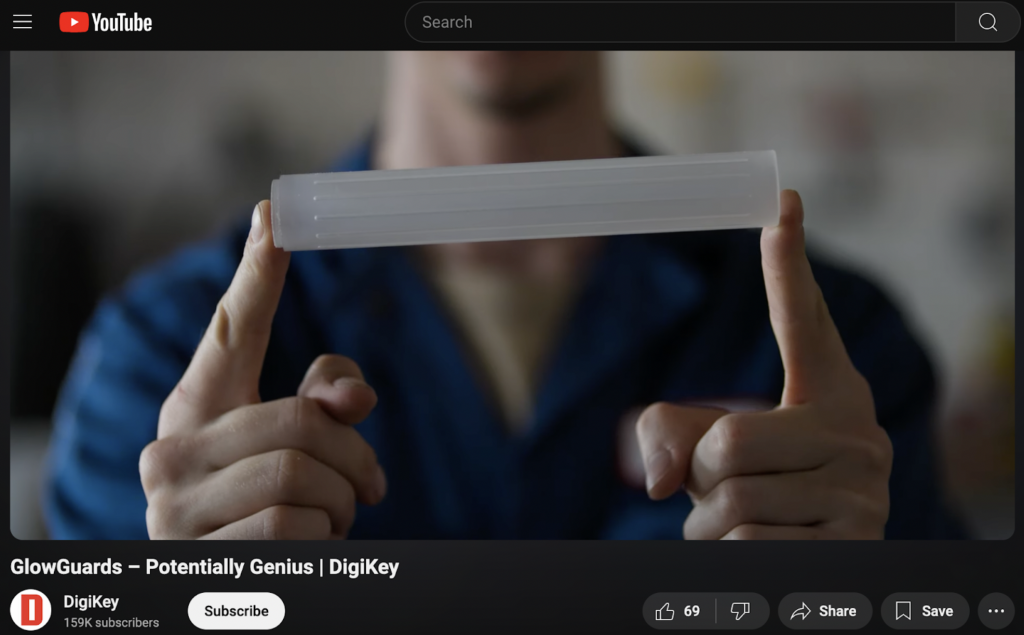

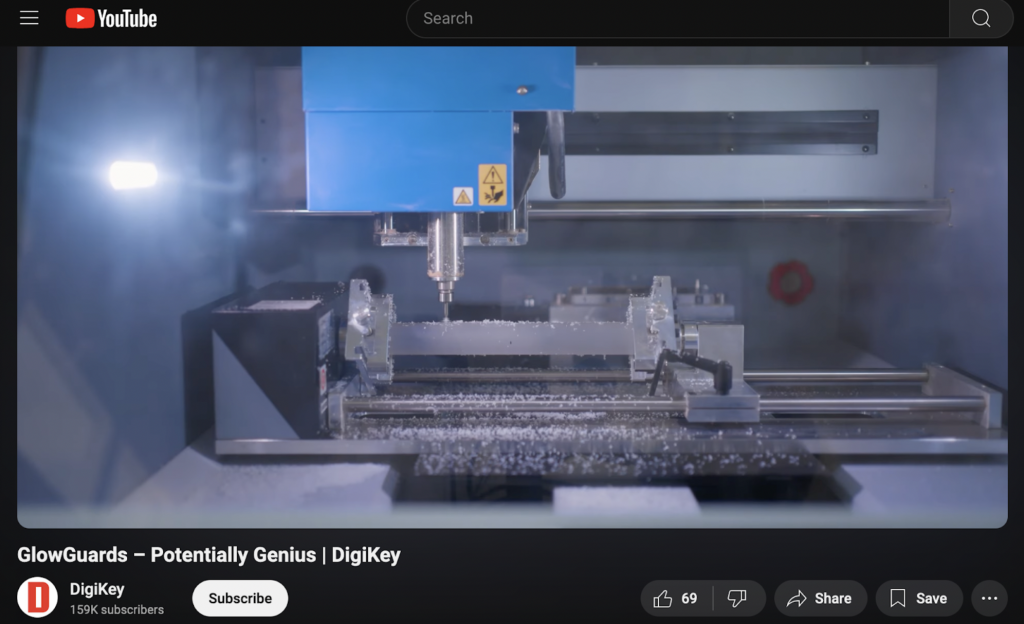

Next, Pepin Gelardi, Tomorrow Lab’s other partner works on the architecture of the product, consisting of the 3D printed enclosure and assembly of all parts and components. The housing must incorporate the light source, connectivity, sensing and power all in one place. Pepin uses a tube and chassis design – the 3D printed tube meets with the clear tube as the light source and the chassis holds all the electronic components, like the LED, ESP32 and batteries. The chassis then slides into the 3D printed tube with the USB port sliding into place on one end and the LED facing out into the clear tube on the opposite end. In order to have the two cylindrical rods fit together, the clear rod is CNC milled to create a groove to fit into the 3D printed rod, and additional exterior parallel details to create an aesthetically pleasing display. Shuang then shows us a modified PCB, containing flat contact beds so that the microcontroller can “hug” the board.

We then come back to Dorian who explains that the board is programmed to send the sensor data straight to Golioth and now that the data is in the cloud, we can manipulate and interpret that data any way we want! But for this device, we are using an alarm mode and heat map mode. Dorian walks us through each: the alarm mode is a visual alert to the user when a sensor goes above a certain threshold value and the heat map mode is a visual analysis of temperature, humidity or TVOC.

Dorian also shows us the Golioth interface, where he plays with the functions that have already been set up on the device, like the neopixel colors, blinking capabilities and on/off switches. He then works on creating the logic states/modes for the alarm and heat map modes.

It’s finally time to show off the final design to Chris Gammell and Jonathan Beri! Ted shows off GLOWGUARDS: a “Scaleable sensor device system to identify sources of environmental issues like humidity, mold, TVOCs or temperature. Using the Golioth platform, each node transmits sensor data to the cloud, which then sends back a heat map color to display on the devices, allowing real time visualization of the issue’s source.” We show the Golioth team how it works! Dorian uses a blow torch to show how the devices react when in heat map mode, showing how only the one affected lights up. They show off the alarm mode when testing the devices with moisture and solder fumes.

So… is this Potentially Genius? Jonathan says YES – “the use of a sensor and a light are fundamentals when designing components, but it’s really when you tie that to software, logic, form factor and all that comes together it becomes useful and not just a bunch of electronics anymore.” Chris exclaimed, “I love the on-site, live heads up display, but then you also focused in on Golioth’s capability to move off platforms, like Node Red, webhooks and pipelines and that is something we are really excited about!”

What an elegant solution for an important need! If sensors are your jam, check out this PG episode on Ozone Sensors and this gorgeous motion activated microphone.