Introduction

As a hardware product development firm, we at Tomorrow Lab love discovering new techniques to create high-quality products for our clients. When it comes to housing, we’ve found that utilizing low-volume methods is often the way to go. We understand how materials are used thanks to our learn-make-test-break-repeat approach.

This comprehensive guide is a tool for our most common processes and materials, perfect for anyone looking to delve deeper into the world of hardware product development through different types of rapid prototyping. Let us share some of our expert knowledge with you through this is Part Two of The Tomorrow Lab Guide to Housing: Low-Volume Methods.

What is rapid prototyping?

In case you missed it, checkout our Part 1 Article Rapid Prototyping Materials & Processes.

Rapid prototyping is a process used to create product or service prototypes quickly. It involves using computer-aided design (CAD) software and 3D printing technology to produce physical models of designs rapidly. These models then serve as testbeds for further refinement before finally entering production.

Moreover, it is often used in product development, allowing designers to identify potential problems and create a better final product. It can also help businesses save time and money by reducing the need for expensive trial-and-error testing.

Additionally, rapid prototyping services can be used to rapidly develop prototypes of services, such as new business processes or customer experiences. By doing so, businesses can quickly test ideas before releasing them into the wild. Rapid prototyping is invaluable for ensuring products and services are ready for launch and achieving maximum market success.

Our services on prototyping hardware

Tomorrow Lab’s rapid prototyping services make turning your creative vision into physical reality easy. We offer comprehensive hardware prototyping solutions that include the following methods:

3D Printing

3D printing, or rapid prototyping, is an additive manufacturing process whereby objects are created from a digital file. Prototyping with 3D printing enables manufacturers to quickly and accurately develop prototypes for product testing without costly tooling and setup times associated with traditional manufacturing methods.

Tomorrow Lab uses a range of different 3D printing technologies, including:

- Stereolithography (SLA) is an optical fabrication process that uses ultraviolet light to harden liquid resin into desired shapes. It produces very accurate parts with high resolution and can be used to create objects with intricate details.

- Selective laser sintering (SLS) uses a laser to fuse small particles of plastic, metal, or ceramic powders into solid three-dimensional shapes. It can produce parts with complex geometries and work with materials like Nylon and TPU.

- Fused deposition modeling (FDM) works by extruding melted thermoplastic filament layer-by-layer onto the build plate to form an object. It is ideal for producing highly detailed parts quickly and cheaply as it has a relatively low setup cost compared to other processes.

At Tomorrow Lab, we leverage our expertise in 3D printing technologies for rapid prototyping to help customers bring their ideas to life. We offer various services from prototyping to full-scale production so that manufacturers can efficiently produce high-quality parts quickly and accurately. With 3D printing, the possibilities are endless!

Casting

Casting is a technology that produces 3D objects with molten materials. This process is typically used to make parts in metal or plastic. It is a versatile and cost-effective way to create complex designs quickly and efficiently. Tomorrow Lab’s metal casting services employ this technology to generate exact parts ready for use right out of the mold.

The company utilizes advanced investment casting techniques to ensure a high-quality surface finish and consistent product. Furthermore, we have developed unique software tools that streamline the design process and drastically reduce project turnaround times.

These technologies are widely used within multiple industries, such as:

- Aerospace

- Medical device manufacturing

- Automotive engineering

- Consumer products

The precision and accuracy of castings make them ideal for applications where complex shapes or intricate designs are required. In addition, the process offers excellent mechanical properties such as strength, wear resistance, and corrosion resistance that can be tailored to specific needs.

Plastic Casting

Plastic casting is the process of creating plastic products using a mold. It’s often used for intricate parts, small batches, or items that have complex shapes and details. The plastic is heated to a melting point before being injected into the mold.

Tomorrow Lab offers professional services for plastic casting with our advanced equipment. Our team of experienced engineers can help you create custom plastic parts for any application. With specialized machinery and expertise, we can assist with small-batch production or large-scale prototyping projects.

Thermoforming

Thermoforming is a manufacturing process that transforms thermoplastic materials into high-quality products. It involves heating the plastic to its softening point and forming it into a desired shape and size using molds or special tools.

Tomorrow Lab specializes in thermoforming, using state-of-the-art machinery to create precision parts with tight tolerances and intricate details, all designed to meet the specific requirements of each customer’s unique application. The services include:

- Vacuum forming

- Pressure forming

- Twin sheet forming

Wire EDM

Wire EDM (electrical discharge machining) is a prototyping technology that uses electrical discharges to cut and shape metal materials. It is a fast, accurate, and precise method of cutting complex shapes and designs with minimal material loss. The technology uses a thin wire (usually made of brass or copper) to cut through the metal material.

Tomorrow Lab is a leading provider of Wire EDM services for prototyping and rapid manufacturing applications. We specialize in intricate designs, deep cavities, and tight tolerances requiring precise cutting.

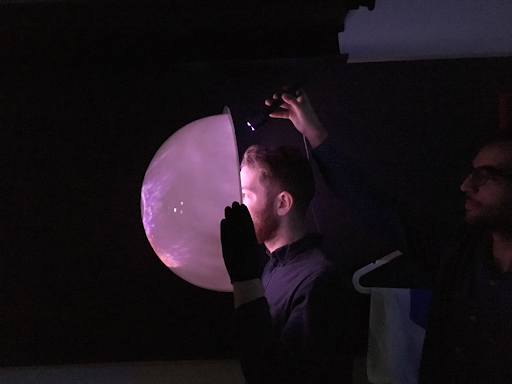

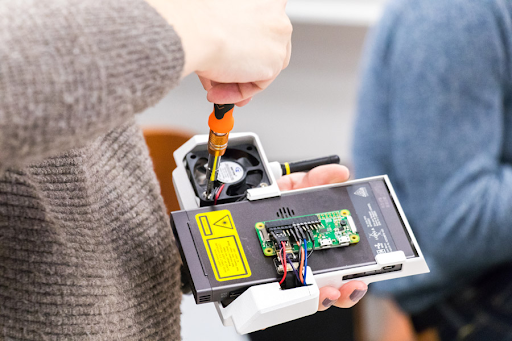

We’re passionate about creating exciting and ground-breaking products

The process of prototyping and hardware development is intricate and time-consuming. At Tomorrow Lab, we strive to provide our clients with innovative yet practical solutions to their problems. Our team works diligently to create well-designed end products that meet our customers’ expectations.

As evidenced by our project QBracelet, we take the time to review all product components before manufacturing them in high numbers. We ensured that the structure, battery placement design, and PCB were all in order as part of an effort for a stylish solution for smartphone charging.

If you are looking for experts passionate about creating exciting and ground-breaking products, please contact us today! We guarantee complete satisfaction and a unique product tailored directly to your needs!

Leave a Reply