Introduction

Packaging plays a crucial role in protecting products during transportation, storage, and sale while also being central to branding and marketing purposes.

Today, consumers expect a wealth of value from their products and are more concerned about sustainability, so brands need to find innovative ways to improve experiences while reducing waste and minimizing the environmental impact of packaging.

At Tomorrow Lab® we see this as a single problem – traditional packaging does not produce enough value

Understanding Traditional Packaging and its Shortcomings

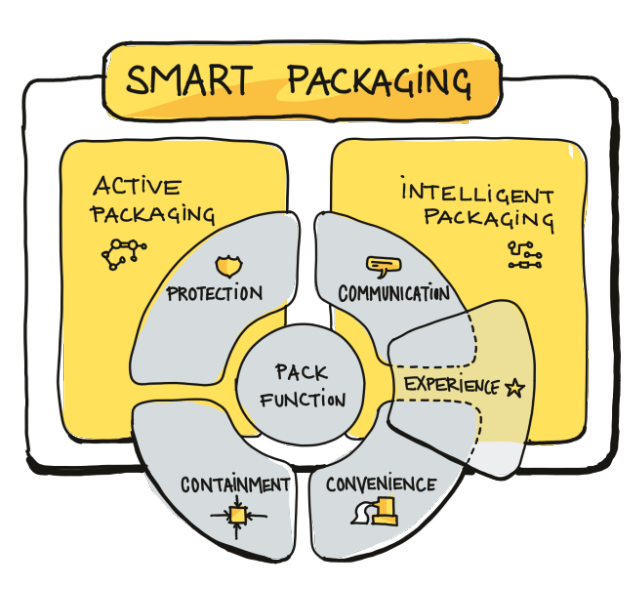

Traditional Packaging serves four overlapping functions: Protection, Communication, Containment and Convenience.

We add to that a fifth function: Experience, which connects functions of the package with external and extended systems in Retail, Home, Commercial and Industrial environments. Examples include Connected Apps, Shelf Displays, Dispensers and Point of Sale (POS).

A typical packaging system consists of Primary (the thing that touches your product and dispenses it), Secondary (the thing that protects and communicates for the primary), and Tertiary packaging (typically a sleeve or shipper that adds communication and protection).

The life cycle of these systems are short. They move from factory to shelf to trash creating a moment of experiential value just before the end.

Overall, the life cycle of a traditional packaging system is linear and results in significant waste. This is why we are looking towards more sustainable alternatives such as smart packaging and circular economy models.

Smart Packaging: The Future of Product Protection

Smart Packaging can be thought of as an enhancement of traditional packaging. It typically falls into two categories: active and intelligent.

Active Packaging: More than Just Containment

Active packaging refers to packaging that has been designed to actively interact with the environment or the product it contains.

This type of packaging often includes features such as oxygen scavengers, moisture absorbers, and antimicrobial agents to help preserve the quality and safety of the product. In short, its goal is to protect the product. Most Active Packaging innovation is powered by Material Science and/or Mechanical Design.

Intelligent Packaging: A Step Forward in Consumer Experience

Intelligent packaging, on the other hand, incorporates sensors and other electronic components that can provide real-time information about the condition and quality of the product as well as its usage.

By using active and intelligent packaging, companies can improve the safety, quality, and sustainability of their products while also providing consumers with a better overall experience. Most Intelligent Packaging innovations are Electronic and/or radio-frequency (RF) enabled

Taken together, Smart Packaging encompasses enhancements that have the power to multiply the value of the product contained inside, but where are the innovation opportunities and how can this improve on waste?

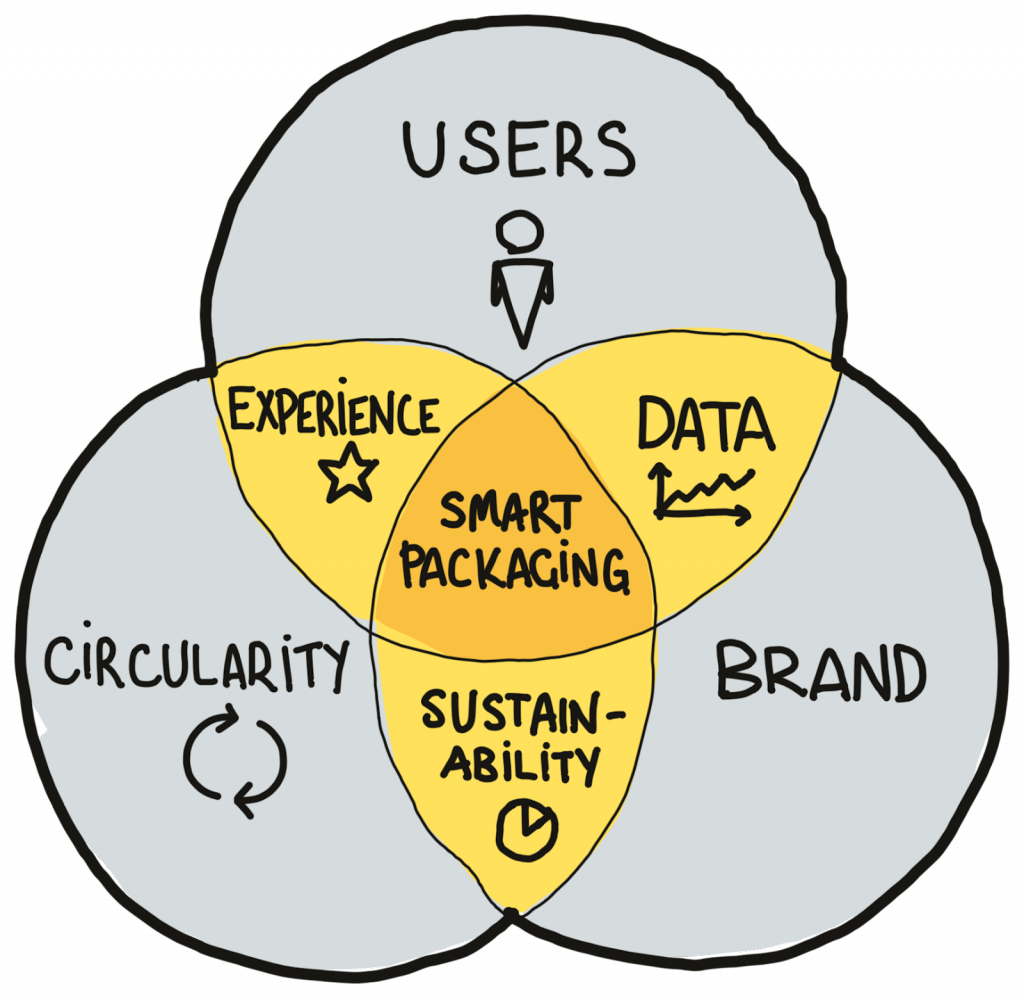

A New Perspective on Packaging: Users, Brand, and Circularity

Packaging Innovation requires us to look at various systems and find where we can generate value in the intersections. After a decade of related projects, at Tomorrow Lab® we think Smart Packaging can be mapped as the intersection of overlapping trifecta: Users, Brand and Circularity.

The inclusion of “circularity” might seem unexpected but this is the crux of our insight. In this case, Circularity refers to the ability of a system to close back in on itself. Examples include reusable and reclaimable packaging; the broader Circular Economy; and systems of exchange where users and brands gain value from each other and help each other to grow.

Circularity empowers completely new value propositions while promoting sustainability. It transforms traditional packaging from a momentary experience into Smart Packaging that creates a powerful, relationship building, revenue generating machine.

Breaking Down the Packaging Value Equation

To that end, at Tomorrow Lab® we are leveraging the experience that a package provides as the driver for circularity. At present, most circular systems present a ‘grudge’– tasks like returning, refilling, or mixing that the user has to do but may not want to do.

But if we elevate the experience and physical interaction of the package, we can make this crucial participation something that the user loves to do. We will cover this in more detail in future posts.

| The Packaging Value Equation We Start with a Product X Contained in a Primary Package X Enhanced by a Smart Layer X Extending an Experience beyond the package = Resulting in holistic Value. |

The ‘Smart Layer’: Bridging the Physical and Digital

Furthermore, at Tomorrow Lab® we see the user experience as a way to expand the value of a product beyond the package in all respects – connecting the factory, retail, usage and digital aspects of the product.

We call the features that allow a package to extend and integrate into a larger experience the “Smart Layer”. It’s what makes a package a smart package. Here are a few examples of Smart Layers:

ID Systems (RFID, NFC, QR) – The most common smart layer are ID systems like RFID that help track a package from manufacturing through logistics, retail, use and recycling. Some systems, particularly QR-based, even provide potential user engagement opportunities through web and AR experiences.

Electronic Sensors and Displays – More advanced systems can track usage and environments, or engage users directly on the package. They provide Brands more detailed insights into usage. We’ve developed smart layers that connect packages to the cloud with and without intermediary devices. A great example is this flashy smart cap we developed for P&G, or this smart pill bottle we developed for AdhereTech.

Mechanical – A mechanical layer allows us to protect and enhance the product and package. A novel dispenser that deploys a preservative is an example – as in this sample collection cup we created for Ro Healthcare. We’ve even developed mechanical systems that mix formulas in the package preserving their efficacy until the moment of use. This system we made for Exponent is a great example.

Material – Utilizing unexpected or novel materials is another way a package can enhance the value of a product. Oxygen scavengers and desiccants are common examples. More unique, the shipping case we developed for Ro Healthcare contains carefully selected insulation and phase-change materials that turn the box into a mini-refrigerator.

Challenges in Implementing Smart Packaging Solutions

Of course we often hear that this is all easier said than done when creating new kinds of packaging. There’s a tremendous status-quo: Packing has to be cheap.

And new packaging solutions need to be made at enormous scales and with high capital expenditure for automation and equipment. And developing new packaging lines takes years. Right? Not necessarily.

An Opportunity for Innovation

We have one great way to help bring smart packaging to market today: Invent Something New. Stop thinking about the package and start thinking about a whole new idea.

The innovation space between consumer packaged goods and consumer devices is a tremendous blue-ocean opportunity – the same goes for commercial goods and commercial equipment.

Our portfolio is full of great examples where we helped our clients look beyond the product vs. package dichotomy and helped them discover an entirely new user experience that leverages both.

If you want to discuss how Smart Packaging can transform your CPG or Commercial or Industrial Products, reach out to us at Tomorrow Lab®. You can head over to our Smart Packaging and CPG industry page and contact us there.